Overview: Types of PEX and Ways to Connect

First of all, what exactly is PEX?

PEX, short for cross-linked polyethylene, is a flexible plastic used for plumbing. The tubing has become quite popular over the years, replacing traditional copper and galvanized steel water supply lines. Homeowners can easily pick up PEX tubing from their local hardware store (or order it online) and complete DIY project upgrades or replace leaking pipes without having a plumber come out. PEX is utilized in over 60 percent of new construction residential water systems—a notable jump in use since its arrival in the US during the 1980s.

Advantages of selecting PEX tubing:

- PEX is safe and easy to install. No soldering required, which can be dangerous and tricky, especially in tight spaces. Flames are cool, but burning your eyebrows off or your home down is not.

- PEX can be connected to existing copper and galvanized steel water supply lines with the use of fittings—small pieces that link the two types of plumbing together.

- Due to its flexibility less fittings are needed, unlike metal piping which cannot bend.

- PEX is more resistant to cracking due to freezing thanks to its ability to expand.

- Unlike copper and steel pipes, PEX does not corrode, avoiding both water contamination and leaks.

- Water travels noiselessly through PEX, which is not always the case with metal plumbing.

- Red and blue PEX tubing make it easy to distinguish between hot and cold supply lines.

- PEX is easy to service and replace, especially if you install a maintenance loop, which includes a loop of extra tubing that allows for cuts—using PEX cutters—and quick fixes.

- PEX is also an inexpensive option compared to copper.

Read why we recommend PEX tubing over copper piping.

A few cons to keep in mind:

- Ultraviolet rays (from the sun) cause PEX to break down quickly, making PEX unsuitable for outdoor use.

- Although PEX is fairly easy to install, specific connectors and tools are needed.

- Currently, PEX cannot be recycled due to its inability to melt like recyclable plastics.

Sizing:

PEX tubing varies in length from convenient 10-foot sections, which are perfect for small repairs or hose bib installs, to 500-foot rolls used for building a home’s entire water supply system.

PEX is available in 3/8- to 1-inch diameters. It’s a good idea to install 1/2-inch or 3/4-inch PEX for your main lines for adequate water flow. When replacing old water supply lines with PEX the standard is to use the same size plumbing, although you can transition from 3/4-inch to 1/2-inch plumbing with an adapter.

Colors:

PEX tubing can be red, blue, white, or gray. Red signifies a hot water line, while blue is used for cold water lines. White or gray PEX can be used for either hot or cold water. Red, blue, and white PEX. Photo: Family Handyman

Red, blue, and white PEX. Photo: Family Handyman

Types of PEX:

PEX-A is the most flexible and is suitable for use in all home water-supply plumbing needs. It is the most resistant to cracking due to freezing, as it can expand the most. PEX-A is more expensive than B or C, and has no major benefit over PEX-B besides its greater flexibility. PEX-A is manufactured using peroxide.

PEX-B is stiffer than PEX-A and has a tendency to want to return to its coiled state. PEX-B can still be installed easily and expands to resist cracking due to freezing as well. PEX-B is manufactured using a moisture-cure method, and has a higher resistance to chlorine, making it a solid choice in regions where water contains higher chlorine levels.

PEX-C is the stiffest of the three types of PEX, making it the most difficult to work with. It is prone to kinking and susceptible to cracks in freezing conditions. PEX-C is the cheapest option, and should only be used for small repairs that don’t require much bending. PEX-C is manufactured via an irradiation method.

Methods used to make watertight PEX connections:

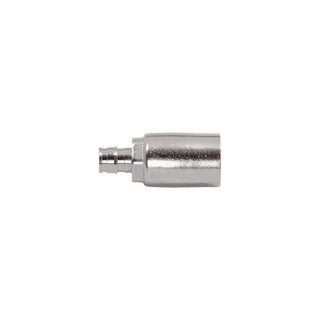

Copper crimping is one of the most popular methods to connect PEX. You’ll need copper crimping rings and a PEX crimping tool. The copper ring slides over the end of the PEX tubing, then a fitting is inserted into the PEX. The copper ring is moved to the end of the tube over the fitting, so that the PEX crimping tool can crimp the copper ring and tube snuggly in place.

Snag a 1/2" PEX Crimp Inlet or 1/2" PEX Crimp 90° Elbow Inlet for your next project.

Crimp Connection. Photo: SupplyHouse.com

Crimp Connection. Photo: SupplyHouse.com

Stainless steel clamps (SSC) is a method that involves using a ratchet clamping tool to tighten stainless steel rings around PEX connections. The steel ring slides over the end of the PEX tubing before the fitting is inserted, similar to the copper crimping method. Then the ratchet clamping tool is used to squeeze a tab on the ring, tightening the ring around the tube and fitting.

Clamp Connection. Photo: SupplyHouse.com

Clamp Connection. Photo: SupplyHouse.com

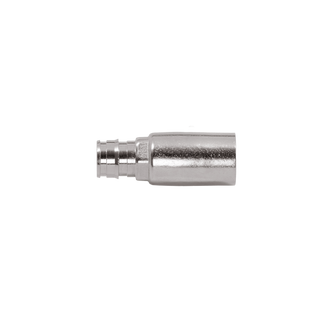

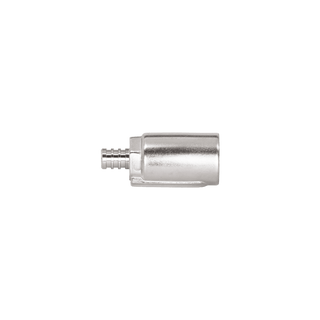

Expansion connections are made by using a PEX expander tool to stretch and widen the diameter of the PEX tube before inserting the end of a fitting. After about 10 minutes, the PEX tubing will shrink back down to create a seal around the fitting. This method only works with PEX-A.

Grab a 1/2" PEX Expansion Inlet or 1/2" PEX Expansion 90° Elbow Inlet to complete your PEX connection. Expansion Connection. Photo: SupplyHouse.com

Expansion Connection. Photo: SupplyHouse.com

Push-fit connections is the quickest method, involving special push to connect fittings that pop onto the end of the PEX tubing, creating a seal. You don’t need tools to implement push-fittings, although a specific removal ring is necessary to take them off of a pipe once they’ve been connected. Push to Connect. Photo: SupplyHouse.com

Push to Connect. Photo: SupplyHouse.com

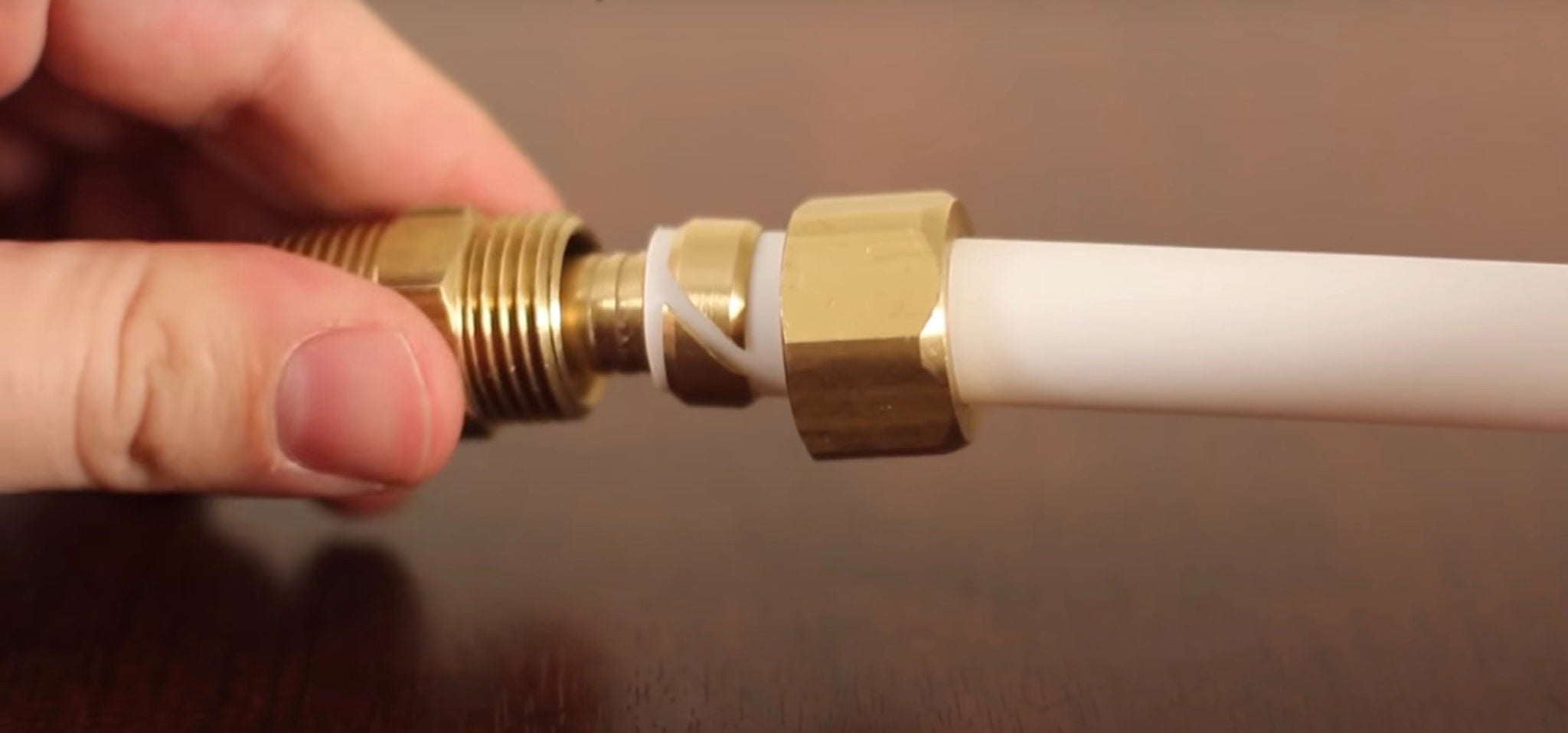

Compression fittings involve slipping a threaded brass nut over the PEX tube before sliding a tapered plastic compression ring in place. Then a hollow brass tube is inserted into the end of the PEX tubing. All of the above is inserted into the end of a threaded fitting, and the threaded brass nut is screwed onto the end of the fitting. The nut squeezes the plastic compression ring against the end of the brass fitting to create a seal as it’s tightened. Compression Connection. Photo: SupplyHouse.com

Compression Connection. Photo: SupplyHouse.com

Here’s a short video showing the above PEX connection methods.

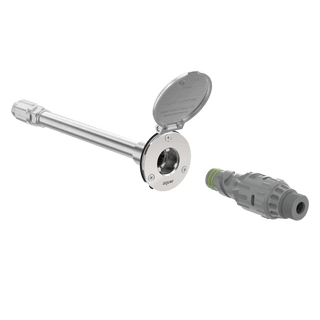

And here’s a simple video demonstrating how to install and connect a V2+ Hydrant to PEX-A using an expander tool.

Make your new Hydrant install a snap with Aquor’s 1/2″ PEX inlets.