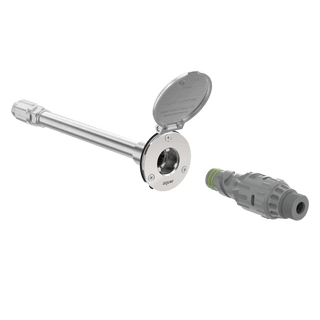

Aquor House Hydrant V1+ Install Guide

Install Aquor's V1+ House Hydrant in 4 simple steps.

Upgrading your water access is easy! Follow along and you'll have your new Aquor hydrant installed in no time.

Click here to watch more install videos.

Installation

Determine the location of the hydrant. The hydrant's stem must be installed into a heated area that will not drop below freezing. Before installation, make sure there is adequate work room for securing the hydrant to the supply line.

Step 1: Prepare the Wall

Prepare the mounting surface and entry hole. Aquor House Hydrants require a smooth, vertical mounting surface to ensure proper installation and draining. Depending on the exterior wall surface, a mounting block may be required to provide a smooth, vertical mounting spot. Mounting blocks can be found in hardware stores, or can be made on-site with materials such as wood, fiber-cement, or PVC trim board. Aquor mounting blocks are available on our website.

Using a 1 1/2” hole saw, bore the entry hole through the wall (and mounting block if using one) in the desired location. Ensure the entry hole is vertically level.

Tip: If drilling through a deep wall, you may need to accommodate for the hydrant's downward angle.

Tip: If enlarging an existing hole, try cutting a dowel of the appropriate size to use as a guide for the hole saw.

Step 2: Secure Hydrant to Wall

Pre-pilot the mounting holes. Make sure to insert the debris cover wedge behind the hydrant faceplate for accurate markings.

Tip: Use a low speed setting or a hand screwdriver to avoid stripping the fasteners.

Secure the hydrant to the wall with the cover wedge behind the faceplate flange. x3 #10 1.5" stainless steel screws are provided.

Tip: Drilling into brick or stone? Consider using specialized fasteners and/or anchors. We also manufacture optional stainless steel mounting plates to space the mounting holes out further if needed.

After securing, test the cover to make sure it opens and closes properly.

Step 3: Attach Fitting

Proceed to the interior of the wall. Before attaching a fitting, unscrew the hydrant's rear inlet from the main hydrant body. The hydrant's default inlet is 1/2" NPT (female). Other optional inlet styles are available. Wrap the appropriate 1/2" NPT fitting in teflon tape then apply pipe joint compound. Thread the fitting into the inlet, then firmly tighten with a wrench.

Once the appropriate fitting is attached to the inlet, re-attach the inlet to the hydrant body.

Tip: The inlets are designed to rotate up to one full turn while remaining watertight, thanks to an O-ring seal. This is useful for alignment, especially for the optional 90° elbow inlets. Tighten the inlet until it stops, then rotate back to the desired spot. This seal is rated to 250 PSI.

Hand-tight is sufficient—do not over-torque the hydrant's body connection. Do NOT apply teflon tape or any kind of sealant to the hydrant's body threads.

Step 4: Connect to Plumbing

With the appropriate fitting securely attached to the hydrant, connect the hydrant to your plumbing system.

Depending on plumbing type (copper, PEX, etc.), the hydrant connection method will vary. Common ways to connect to copper plumbing include soldering and utilizing push-fit adapters.

Tip: With copper plumbing, consider securing the hydrant's inlet to a stud, so the hydrant can be removed from the building's exterior if needed. The hydrant faceplate and body can be rotated out and re-attached to the inlet.

Common ways to connect to PEX include using crimp rings, expansion tools, and push-fit adapters.

Tip: With PEX tubing, we recommend adding an expansion loop inside the wall if possible. This allows the entire hydrant and fitting assembly to be inspected and serviced from the exterior of the building if needed.

Complete the installation by turning on the water supply.

If using a connector without a ball valve for flow control, attach a garden hose to the connector before plugging it in.

Connect to the hydrant, and water should flow.

Disconnect and ensure the hydrant drains and remains leak-free. Inspect the hydrant and plumbing connections for any leaks.

Operation

Operating Aquor House Hydrants is a simple process. Water starts flowing through the hydrant when the hose connector is plugged in. Turn off the hydrant by unplugging the hose connector. Attach the Aquor hose connector to any garden hose. The connector can stay attached to the hose—there is no need to remove it after every use. Before storage, depressurize your hose by squeezing the nozzle on the other end.

Some Aquor hose connectors have a one-way check valve to prevent water from spraying when you disconnect.

Use any accessory as you would with a traditional bib. Inline ball valves, timers, splitters, vacuum breakers, etc. can be attached to the connector.

Connect: Line up the three helical grooves on the hose connector with the three nibs on the hydrant faceplate. Simultaneously push and twist the connector clockwise in a smooth motion. Make sure to align the grooves fully and push in before twisting. Water flow will start instantly when the connector is engaged.

Disconnect: Push the connector in slightly, then untwist counter-clockwise. The hydrant will drain any remaining water left in the body. It is perfectly normal for the water to drain for a few moments.

Always remove hoses during freezing temperatures, remembering to depressurize your hoses before storage. For the longest lifespan, store your Aquor hose connectors out of the elements as well.

Tip: If you leave the Aquor connector attached to your garden hose, make sure to depressurize the hose after use. Temperature changes can cause water inside to expand, causing excessive pressure on the connector's internal check valve (and your nozzle or accessories) over time.

For installation or other technical questions, please call our customer service team at (800) 458-1749.

Maintenance

Aquor hydrants leave the factory fully tested and operational. They are treated with an FDA approved lubricant where needed. The hydrant requires no scheduled maintenance to provide a long operational life. If a problem does arise, all the serviceable components are offered in repair kits.

It's best to disconnect the hydrant when not in use. The hydrant can only offer freeze protection when disconnected. We recommend unplugging after each use.

For freeze protection, the hydrant does not need to be covered any further. As long as it has been disconnected, allowed to drain, and the ambient temperature inside the wall remains above freezing, the hydrant and the plumbing will be protected.

Storing your hose connectors out of the elements can prolong their lifespan. You can drain your hose and bring it inside—the internal check valve prevents unwanted draining afterwards, so your floor stays dry.

Protect the hose connector's O-rings. They are designed for extremely long lifespans if used properly. Use care not to snag the connector O-rings on the hydrant nibs. When connecting, line up the grooves before attempting to push or twist.

Routine cleaning with soap and water is usually sufficient to maintain corrosion resistance and the appearance of the marine-grade stainless steel. Use a soft brush to remove any dirt, then rinse with clean water. Use stainless steel polish as needed.

If you have hard water buildup, the hydrant can be completely disassembled for service or cleaning. The inner valve and stem are accessed through the rear.

You may periodically clean and lubricate the O-rings if there is mineral buildup.

See the full install guide here.